Driving on the road requires peace of mind, knowing your vehicle’s systems are functioning optimally. A reliable braking system is a crucial component of this tranquility, ensuring your safety and the well-being of fellow commuters. However, brake lines, like any other mechanical part, are prone to wear and tear, demanding prompt attention when issues arise.

Image: www.youtube.com

If you notice any warning signs, such as unusual noises or a spongy brake pedal, it’s imperative to take action swiftly. Damaged brake lines can cause hazardous fluid leaks, compromising the system’s functionality and leaving you vulnerable on the road. To prevent such scenarios, equip yourself with the knowledge to detect, diagnose, and resolve brake line problems effectively.

This comprehensive guide will delve into the intricacies of brake lines, focusing on the use of compression fittings for swift and secure repairs. Whether you’re a seasoned mechanic or a DIY enthusiast eager to master this valuable skill, this in-depth tutorial will empower you to restore your brake lines to pristine condition, ensuring a safe and reassuring driving experience.

Understanding Brake Lines: A Foundation for Effective Repairs

Brake lines serve as the arteries of your vehicle’s braking system, carrying hydraulic fluid from the master cylinder to each wheel. This vital fluid transmits the force applied to the brake pedal, actuating the calipers or wheel cylinders to clamp down on the brake pads or shoes. The resulting friction slows or stops the wheels, enabling you to control your vehicle’s speed and bring it to a halt when necessary.

Compression Fittings: A Reliable Approach to Brake Line Repairs

When a brake line succumbs to damage, swift intervention is paramount to maintain the system’s integrity. Compression fittings offer a time-saving and dependable solution for mending these crucial lines, eliminating the need for complex welding or specialized tools. These fittings consist of three primary components: a body, a sleeve, and a nut. The body houses the damaged line segment, while the sleeve slides over the line and compresses it against the body when the nut is tightened. This compression creates a leak-proof seal, restoring the line’s functionality.

Assessing the Damage: Identifying Brake Line Issues

To effectively address brake line problems, it’s crucial to accurately diagnose the nature of the damage. Careful examination of the lines can reveal telltale signs of wear, corrosion, or physical impact that may have compromised their integrity. Common indicators of brake line issues include:

- Visible leaks or seepage of brake fluid

- Dents, kinks, or bulges in the lines

- Rust or corrosion on the line’s surface

- Unusual noises, such as squealing or hissing, during braking

If you encounter any of these symptoms, it’s essential to take prompt action to prevent further deterioration and potential safety hazards.

Image: truediy.net

Embarking on the Repair: Step-by-Step Brake Line Mending

Once the damaged brake line has been identified, follow this comprehensive step-by-step guide to restore its functionality using compression fittings:

-

Safety First: Gather the Necessary Tools

Securely park your vehicle on a level surface and engage the parking brake to ensure stability. Gather the necessary tools, including a flare nut wrench, a line wrench, a tubing cutter, and compression fittings that match the diameter of your brake lines. -

Prepare the Brake Line: Precision Cutting and Flaring

Identify the damaged section of the brake line and use the tubing cutter to excise it cleanly. Next, employ the flaring tool to create a uniform flare on the cut end of the line, ensuring a secure seal within the compression fitting. -

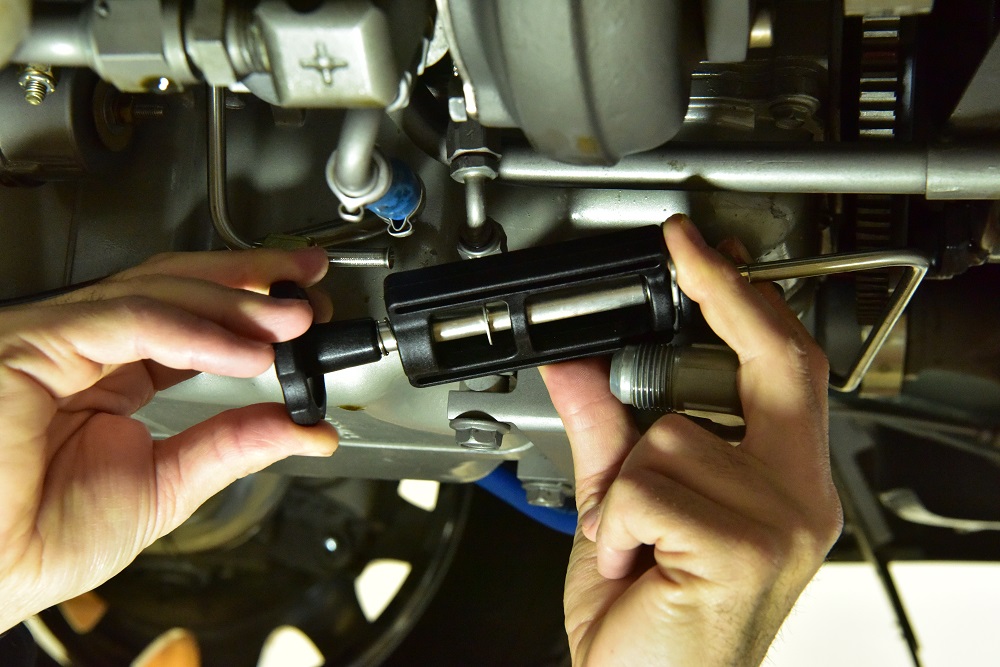

Assembling the Compression Fitting: A Step-by-Step Process

Slide the sleeve onto the prepared brake line, followed by the body of the compression fitting. Carefully insert the flared end of the brake line into the fitting’s body. Finally, thread the nut onto the body and tighten it securely using the flare nut wrench. -

Final Tightening: Achieving Optimal Seal

To complete the repair, utilize the line wrench to tighten the compression fitting’s nut firmly. However, refrain from overtightening, as this could damage the fitting or weaken the brake line. -

Bleeding the Brake System: Restoring Optimal Performance

After replacing the damaged brake line, it’s essential to bleed the brake system to eliminate any trapped air bubbles that may impair its functionality. Start by opening the bleeder valve on the furthest wheel cylinder or caliper, using a wrench to loosen it slightly. Next, have an assistant depress the brake pedal slowly and steadily while you monitor the fluid flowing out of the bleeder valve. Continue this process until clear brake fluid, free of air bubbles, emerges from the valve. Repeat this procedure for each wheel cylinder or caliper, ensuring that the entire system is thoroughly bled.

How To Fix A Brake Line With A Compression Fitting

Conclusion: A Restored Brake Line and Enhanced Driving Confidence

With the successful repair of your brake line using compression fittings, you have not only restored the integrity of your vehicle’s braking system but also instilled a sense of confidence behind the wheel. Your prompt attention and meticulous execution have contributed to a safer and more enjoyable driving experience for you and those sharing the road.

Remember, maintaining a well-functioning brake system is crucial for your safety and the well-being of others. Regular inspections, coupled with timely repairs using appropriate techniques, will ensure that your vehicle’s brakes remain in peak condition, providing you with the peace of mind and control you deserve while navigating the roads. Whether you embark on future repairs yourself or entrust them to a qualified mechanic, the knowledge you have gained from this comprehensive guide will empower you to make informed decisions and navigate the world of brake line maintenance with confidence.